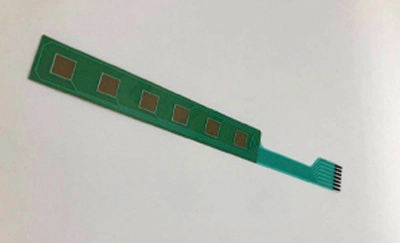

The circuit is the most important factor for evaluating the inherent quality of the membrane switch. The circuit should be constrained by parameters such as current, resistance, withstand voltage, insulation, and life. This is also the penetration of screen-printed products into the multifunctional and high-tech fields. Specifically, to ensure the function of the circuit.First of all, the quality of the screen printed silver paste circuit should be guaranteed and a brief description of how to make the circuit screen

Before making the electric network version, we must first consider the circuit parameters and the structural elements in the circuit to make the requirements of the screen.

(1) The metal silver contact of the membrane switches should be screen printed with a conductive carbon paste protective layer. Due to the physical properties of the carbon paste layer, the following functions can be formed: The carbon paste is a non-metallic conductor and does not combine with oxidation in the air. This protects the bottom metal silver contacts from oxidation; carbon has a small coefficient of friction and is a solid lubricant. When it acts on the switch contacts, it is helpful for rapid separation after the contacts are closed. Carbon has a higher Abrasion resistance and can improve the wear resistance of the switch contacts, ensuring that the switch contacts can withstand millions of contacts. The dense carbon coating can hinder the migration of silver ions, thereby effectively protecting the electrical performance of the switch Stable, when the carbon coating acts on the lead socket, it can facilitate the insertion and extraction of the lead and the connection terminal. Because the thick carbon coating is prone to peeling off, the screen printing conductive carbon paste should not be too thick.

(2) The density of the conductive pattern: Although the thickness of the conductive pattern is the basis for laying the performance parameters of the switch. Since the circuit pattern printed by the membrane switch is formed by the aggregation of particles of conductive metal (usually silver particles), printed on its In the material (silver paste), the barrier between the resin connection to the particles, the impurities to the conductor particles, and the screen mesh wire to the metal particles during the screen printing process will affect the density of the conductor pattern, thus Affect the performance of electrical parameters. For the above reasons, in order to allow conductive printing materials, especially the flake-shaped silver particles in the silver paste to pass smoothly, it is necessary to select a slightly lower mesh, and the wire diameter is required to be thinner and the hole width is relatively larger.

(3) The thickness of the conductive pattern: the resistance of the wire made of the same conductor is inversely proportional to the cross-sectional area of the wire, and the current passing through is proportional to the cross-sectional area. The thickness of the circuit pattern printed by the membrane switch keypad is the basic condition for ensuring the performance of the switch. Therefore, in the screen-making process, the thickness of the screen film must be selected to ensure that sufficient conductor circuit patterns are obtained.

(4) The smoothness of the conductive pattern: the uncleanness of the circuit pattern refers to the sharpness of the edge. It is not only for appearance considerations but more importantly, considering the impact on the electrical parameters, the unclean wires will likely make The edge impedance of the adjacent wire decrease, especially in high temperature and high humidity, it is easy to cause silver ions to extend along the edge of the wire and produce silver ion migration, resulting in a short circuit between the wires and failure of the touch keypad membrane switch.

(5) The life of the conductive pattern: the conductive pattern has sufficient thickness, which not only provides favourable conditions for the passage of current and the reduction of resistance but also improves the high wear resistance of the switch contacts in the pattern.

If you want to know more information, you could contact us –leading membrane keypad manufacturer - info@niceone-tech.com