The Ultimate Guide to Silicone Rubber Keypads

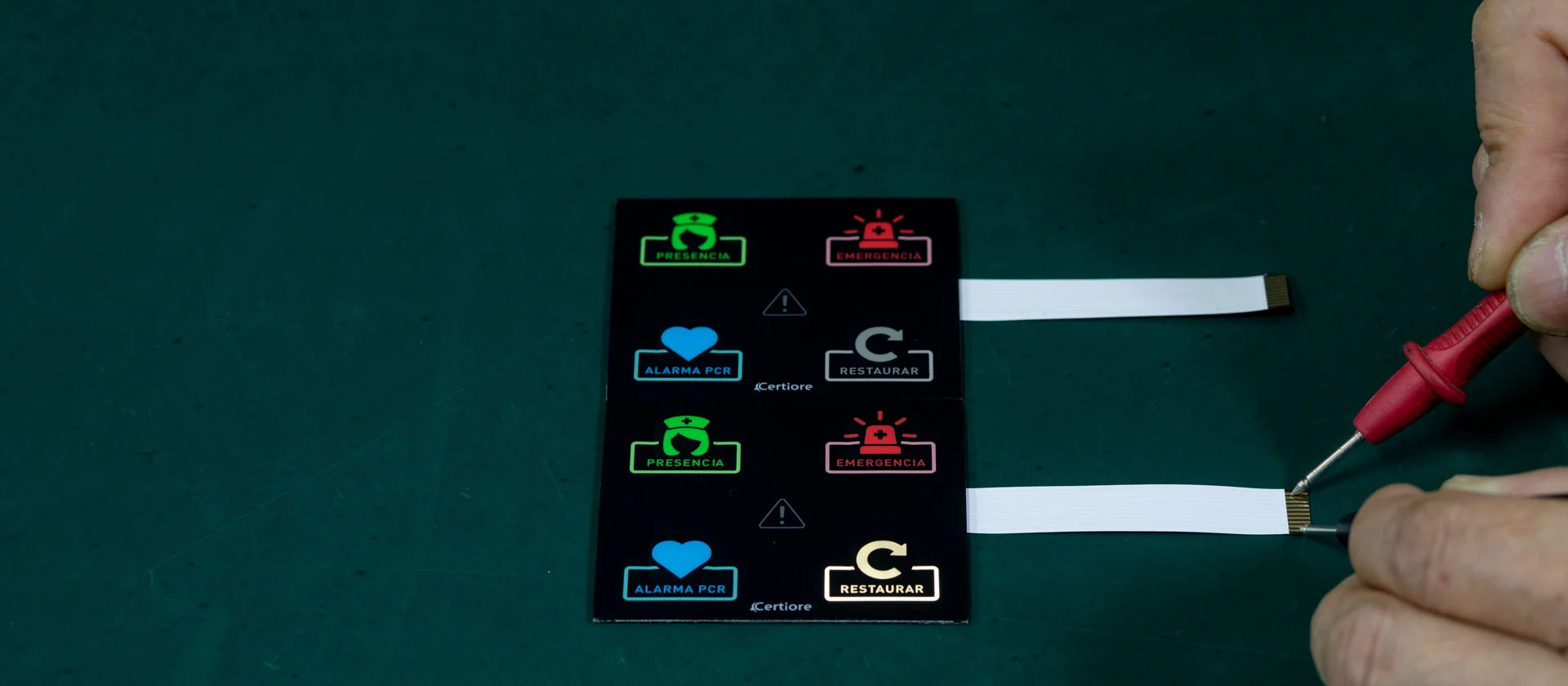

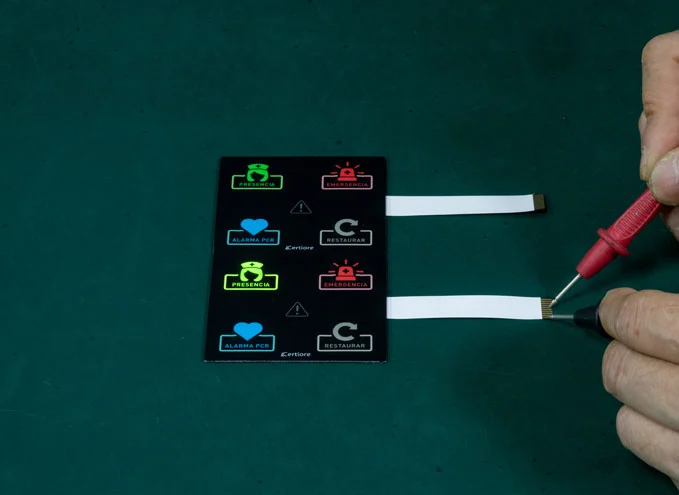

Introduction to Silicone Rubber Keypads

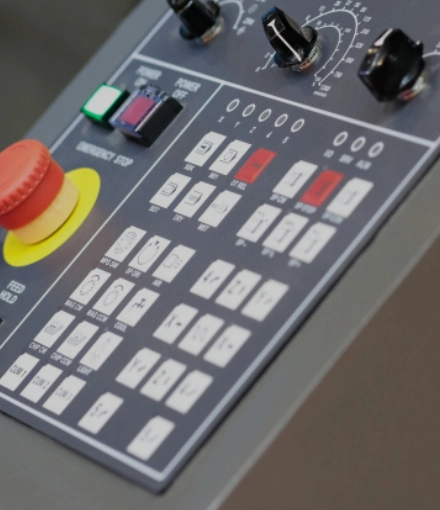

In the world of electronic devices, silicone rubber keypads have become increasingly popular due to their durability, flexibility, and cost-effectiveness. These keypads are used in a wide variety of applications, from remote controls to medical devices. This article will provide a comprehensive overview of silicone rubber keypads, their advantages, and the key considerations when designing and manufacturing them.

Components of Silicone Rubber Keypads

Silicone rubber keypads are made of several components, each playing a crucial role in its functionality and durability:

Silicone Rubber: This is the primary material used in the production of these keypads. It is a high-performance elastomer with excellent resistance to environmental factors such as UV light, ozone, and extreme temperatures.

Carbon Pills: These are small pieces of conductive material placed underneath the keys. When a key is pressed, the carbon pill makes contact with the circuit board, completing the circuit and sending the signal.

Conductive Ink: This is a special type of ink that is applied to the underside of the keys. It enhances the conductivity of the keys and helps in the transmission of the electrical signal.

Protective Coating: A protective coating is applied to the surface of the keypad to protect it from wear and tear, as well as environmental factors.

English

English français

français Deutsch

Deutsch Español

Español italiano

italiano português

português dansk

dansk Suomi

Suomi Polska

Polska Svenska

Svenska Nederland

Nederland