Membrane switch can be called a light touch keyboard, using sheet material, adhesive tape, LEDs, metal dome, backplane and indicator elements combined into electronic accessories. The front of the Membrane switch will display the marks, symbols, LCD window, Leds window, and buttons. It is a new type of electronic component.

Relative to mechanical switches. Membrane switches have the advantages of good waterproof, dustproof, moisture-proof, cleaned, oil-proof, corrosion-resistant, stable performance, small size, light weight, customizable, and UV resistance. Membrane switch is divided into Rigid or flex membrane switch. According to the feel, it can be divided into Tactile and Non-tactile membrane switch, according to the method of screen printing, it can be divided into digital printing membrane switch and screen printing membrane switch. No matter which kind of Membrane switch has its outstanding superior performance.

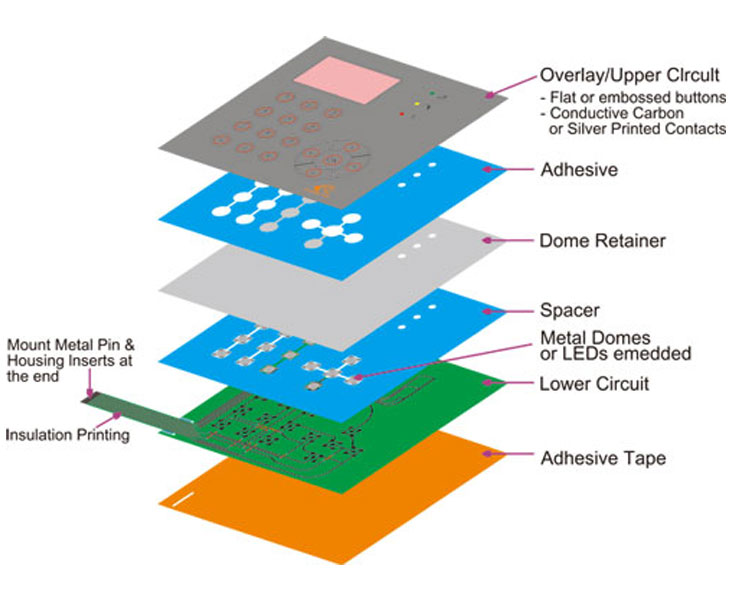

Overlay-

Polyester and Polycarbonate is usually the first choice for membrane switch keypad materials. If it is simply a panel instead of a membrane switch keypad, Lexan and Polyester are also good choices. The overlay is the most intuitive form of human-machine interface. Niceone-tech will screen print or digital print on the back of the material, and they can also be used in combination. Special requirements such as mirror silver effect are also feasible.

Overlay adhesive

As the first layer of adhesive paper under the panel, the Acrylic adhesive is usually used, generally the thickness is between 0.125-0.225mm. If it is LGF membrane switch keypad structure, the thickness sometimes reaches 0.64mm.

Top Circuit Layer (Dome retainer)

This layer usually has three functions: 1. As the Dome Retainer, it ensures that the Snap dome of the circuit layer will not form shrapnel movement due to triggering and closing, resulting in circuit failure and circuit wear. 2. Use 0.1-0.125mm Polyester printing conductive ink, carbon oil, and UV ink as the upper line. This layer structure can also be convex to make tactile feedback better. 3. Can be used as an ESD shielding layer.

Circuit Spacer (switch spacer)

Both upper and lower lines are printed with conductive ink, usually thicker tape is used to separate the upper and lower lines to avoid direct conduction of the membrane switch keypad. If the upper circuit is only used as a fixed layer, then the general thickness of the Overlay adhesive + Top Circuit Layer + Lower Circuit Layer should be greater than 0.4mm, otherwise, the panel will squeeze the shrapnel to make them feel worse. Unless the panel is convex, the four-layer structure is less than 0.4mm.

Lower Circuit Layer

The thickness of this layer circuit is usually 0.1-0.188mm. It can be printed with ink, carbon oil, and UV ink. LEDs can also be installed. Some membrane switch keypads will choose the copper flex or Printing circuit Board as the circuit. Compared with Polyester, their performance will be more stable. More often applied to the medical and military industries. If it is copper flex or Printing circuit Board as a line, Niceone-tech can even install a variety of components on the line.

Rear Adhesive

There are many choices, but the most commonly used are 3M200MP series or 3M300LSE. According to the different products of membrane switch lamination, Niceone-tech will recommend 3M300LSE if it needs higher viscosity.

Rigid Support Layer

This layer structure is generally used as the last layer of the membrane switch keypad, which can make the structure of the membrane switch keypad component more complete. Usually, the choice of materials is AL, FR4, PC, or steel. If AL is selected, nuts or feet may sometimes be added to the back of the product.

Non-tactile membrane switch:

An important difference between Non-Tactile membrane switch and Tactile membrane switch is that there is no mechanical movement-when the buttons are pressed, there is no feedback response. At the same time, Non-Tactile Membrane switches are basically flat surfaces without protrusions, but they also have embossed outer edges. Non-Tactile membrane switch allows the operator to quickly locate the button. The product has no tactile feel and no metal dome, but it has obvious cost advantages and is easier to clean. Unlike the tactile feedback of Tactile Membrane Switch, Non-Tactile Membrane Switch feedback reflects whether the button is activated or not through the color change of LEDs and the change of LCD screen content.

Tactile membrane switch

Tactile membrane switch can also be called momentary membrane switch. Tactile means has feedback. When the operator presses the switch button, the operator can clearly feel the tactile sensation given by the button and the sound from the button. This is due to the deformation of the Dome. If the pressure is removed and Dome returns to its original state, the circuit connection is interrupted.

The main application material of Membrane switch is Polyester or Polycarbonate. The material is mostly transparent, and different color patterns are formed on the back of the material by printing ink. Different materials have different characteristics, the main characteristics-UV resistance, chemical resistance, antibacterial, easy to clean, etc. So consider that the material needs to be selected according to your product application, and you need to choose UV resistant outdoors. The laboratory needs to be resistant to chemical substances and easy to clean. There is also a cost option, so the material panel needs to be cost-effective, then the silicone rubber keypad can also be used as a priority option.

Waterproof performance-Marine equipment may have higher requirements for Membrane switch, which requires Membrane switch to have the characteristics of waterproof masket or reach IP67 rating.

Silver migration problem-In a high voltage and high humidity environment, Polyester's Flex silver circuit usually encounters short circuit problems caused by the migration of silver oil, so it is necessary to use a better performance Flex copper circuit.

Resistance problem-The resistance of Membrane switch is usually less than 150 ohms, but sometimes the line is too long and it is a silver flex membrane switch Then the resistance may be too large. At this time, you need to choose a gold-plated metal dome or thicken the silver oil circuit to make the resistance less than 150 ohms. A more direct method is to use Flex copper membrane switch or PCB membran switch.

Newton ring-Membrane switch adds polycarbonate as a window, there will be a gap in the middle. At the same time, Newton's rings may occur due to air transportation problems. The solution is to screen UV dots on the PC window to solve the problem.

The above are just part of the things that need to be considered when making membrane switch. If you need more detailed information, you can contact our team.