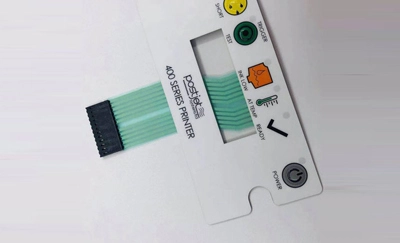

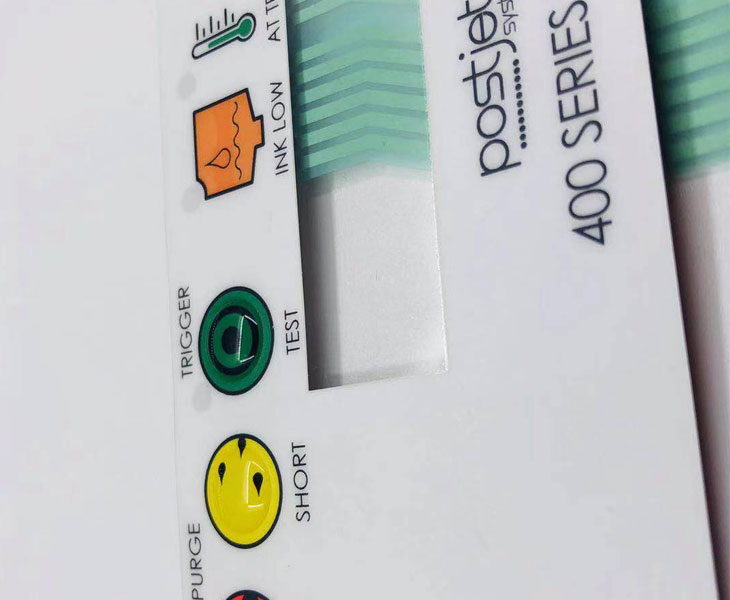

LEDs membrane switches are very popular in the electronics industry market. You may not know what LEDs membrane switches are, but you must have seen them on treadmills, electronic remote controls and medical equipment. Perhaps the membrane switch looks very light and not so eye-catching. But its internal structure is very different. If you understand the structure of the product better, you will be more comfortable when you use this product.

LEDs membrane switch can be composed of 4-8 levels.

The four-level LEDs membrane switch consists of the following integrated layers:

1. Overlay- The most common way is to use screen printing to print on 0.1-0.5mm sheets. You can usually customize text, logos and patterns.

2. Adhesive: The main function is to glue the Overlay and the bottom layer together

3. Circuit: Printed with conductive ink to arrange the electrical properties required by customers. PCB and FPC can also be used as circuits, when customers need smaller circuits or more complex circuits.

4. Adhesive: A final adhesive sheet is placed on the back of the switch to aid in the assembly of the final device.

This type of four-layer structure LEDs membrane switch does not have a metal dome. This type of structure has a lower cost and is suitable for products that consider cost effects. Since the LEDs membrane switch has LEDs inside, the height of the LEDs is about 0.3-0.8mm, so if the panel has no buttons, you can choose to increase the adhesive thickness to 0.4-0.9mm, or you can reduce the thickness of the membrane switch by embossing. If the product has a button function, then the LEDs windows must be embossed, otherwise the panel window will be broken.

The 6-level LED membrane switch consists of the following integrated layers, which is also the most common membrane switch structure.

1. Overlay: The most common way is to use screen printing to print on 0.1-0.5mm sheets. You can usually customize text, logos and patterns. Most of the time the product needs buttons and LEDs windows to emboss. The shape of the bump depends on the customer's needs.

2. Selective adhesive: The main function is to glue the overlay and the bottom layer together

3. Tactile Layer: Fix the metal dome to avoid displacement of the metal dome during use. When the product needs static electricity protection, we can also use PI or printed ESD on this layer to prevent static electricity from damaging the product.

4. Spacer: Separating the top and bottom circuit layers, the spacer is typically formed from heat-stabilized polyester in between two layers of acrylic adhesives.

5. Circuit: Printed with conductive ink to arrange the electrical properties required by customers. PCB and FPC can also be used as circuits, when customers need smaller circuits or more complex circuits.

6. Mounting Adhesive: A final adhesive sheet is placed on the back of the switch to aid in the assembly of the final device.

The 8-level LEDs membrane switch board is basically the same as the first 6 levels of the 6-level membrane switch, but the seventh is slightly different. The main reason is that metal dome and LEDs cannot be installed in the circuit at the same time, or you want to save cost without using FPC or PCB as the circuit.

7. LEDs Circuit: Assemble the LEDs on the bottom, saving the shrapnel circuit layout of the sixth layer.

8. A final adhesive sheet is placed on the back of the switch to aid in the assembly of the final device.

As LEDs membrane switch can add some functions and components, the product will be more outstanding, and even the product can be used more widely.

1. Backplane: It is used as a supporting function and is an accessory of independent membrane switch. Optional materials are FR4 or metal backplane.

2. Shielding: To prevent EMI and radio frequency interference, add a layer of antistatic printing, which can be led out to ground through a lead wire or extra pin.

3. OCA: Sometimes customers need to directly attach the window to the panel instead of attaching to the surface glue. At this time, it is necessary to use OCA adhesive tape, and at the same time, vacuumize to avoid the generation of bubbles in the bonding of the window and the panel.

4. Increase the protection of Mylar to the circuit: sometimes the electronic accessories are sharp and easy to scratch the product circuit protection ink, then choose Mylar to protect the product circuit and make the product more durable.

5. Waterproof structure: By compounding the circuit structure to form a waterproof structure, the LED membrane switch can even achieve IP68 waterproof level just as a regular sealed membrane switch.

6. Epoxy: transfer the silicone rubber keypad to the membrane switch to make the product more beautiful, and at the same time increase the additional value.

High-quality LEDs membrane switches are widely used in various industries. How to choose a suitable product, then we need to understand the structure of the product, which is why Niceone-tech has integrated this information. Hope this information can help customers who need to buy LEDs membrane switch.