The global market share of medical equipment products is increasing, approaching US$400 billion. Because of this, among the huge market share, the share of membrane switches in the medical market is also increasing. Niceone-tech has also been asked by many factories that make medical equipment how to create a membrane switch that is more suitable for medical use? To answer this question, we must first understand the challenges that membrane switches may encounter in medical equipment and medical systems. As long as these five challenges can be overcome, there will be no major problems in producing and designing an excellent medical membrane switch.

1. Face the challenge of more pollutants such as bacteria and chemicals.

The use environment of medical equipment and medical systems is compared with other conventional equipment. Because there are more patients and medical drugs in hospitals, they are facing more contamination by bacterial pathogens and chemical agents. This is one of the most direct and critical challenges of man-machine interface membrane switches.

2. The sensitivity of the product is challenged (it can also be said that how to enhance the life and durability of the product)

It is very important for medical staff and patients to provide timely feedback during the use of medical equipment. Since the membrane switch in medical equipment is one of the most frequently used accessories with medical staff and patients, it is a challenge for many membrane switch panel manufacturers to maintain the sensitivity of the membrane switch that has been used for a long time.

3. Product-friendly design

For medical staff, how to judge whether the equipment is successfully input operation instruction is more difficult before, and it can only be judged by observing the action of the overall medical equipment. So how can medical staff not waste more time interacting with medical equipment? This is also a challenge for membrane switches.

4. Product tightness

Most medical equipment is often disinfected with a disinfectant. After a long period of wiping, how to avoid the short circuit caused by the product water problem is also a problem and challenge that we often encounter.

5. Use medical equipment in low-light environments.

In recent years, Niceone-tech has been asked a question by multiple medical customers. Sometimes in a dark environment, our patients want to use medical equipment, but cannot confirm that the keys are pressed incorrectly many times. Is there a way to make the keys of the membrane switch glow in a weakly lit environment? Quickly letting patients send requests to medical staff in an urgent environment is also one of the challenges.

Is there no way to overcome these challenges? The answer is, of course, such challenges can be overcome. Remember when the first membrane switch was designed, who would know that it can be installed with lights and will be used in so many fields. The following are some of Niceone-tech's personal views on this type of challenge.

1. Overcoming challenging methods such as bacteria and chemical substances.

The part of the membrane switch board that directly contacts germs and chemical pollution is the panel, so we can choose antibacterial material or antibacterial silicone rubber keypad as the product panel. This type of panel material effectively cuts off bacterial cross-contamination, and at the same time can penetrate the cell wall to destroy the bacterial activity. At the same time, the antibacterial material and silicone rubber keypad have better chemical resistance, so the most important reason for the success of this challenge is the advancement of material technology.

2. Improve the sensitivity of the product (it can also be said to enhance the life and durability of the product)

The sensitivity of the product is mainly manifested in that the product can still provide feedback when the user presses the button of the product after a long period of use. There are 5 main problems that the product has to solve for long-term use

A. The silver oil adhesion of the line needs to be improved.

After the membrane switch is used for a long time, the silver oil will gradually oxidize and fall off. If the resistance of the product increases, the button function will fail and the resistance will increase, making the product lose its sensitivity. Choosing excellent conductive silver oil and enhancing adhesion can solve these problems. Or you can directly use FPC line to make FPC membrane switch. Such problems can also be solved directly.

B. Control the resistance below 100 ohms.

When the resistance of the electronic device is too high, it is difficult for the product to turn on, and the membrane switch will also have this kind of problem. One reason for the resistance is that when the overall circuit is too long, the resistance will be higher. When the lead wire is 200-300mm long, we will print thicker conductive ink or choose FPC or PCB as the circuit control resistance.

C. Metal dome choice.

There are two factors affecting metal dome, one is the size, if the shrapnel is too small, the life may only be 100,000 times. Gold-plated or nickel-plated shrapnel will reduce the resistance of the product and increase the sensitivity of the product. Therefore, we often recommend that medical equipment manufacturers choose the metal dome of the membrane switch to be 8-17.7mm nickel-plated or gold-plated metal dome.

D. Selection of panel materials.

Polyester is better than Polycarbonate as a medical panel. Because the flexibility of Polyester will not change much even millions of times, but Polycarbonate will crack after more than 100,000 times.

E. The use of adhesive tape.

3M adhesive tape is highly recommended. The high-strength adhesive force meets most of the use environments. Will not cause product peeling problems due to long-term use.

F. Improve product tactile feedback.

It is recommended that customers can use higher-priced hardware molds for bumping, so that the button bumps will be more hand-feel and will not be deformed after long-term use.

1. Product-friendly design scheme.

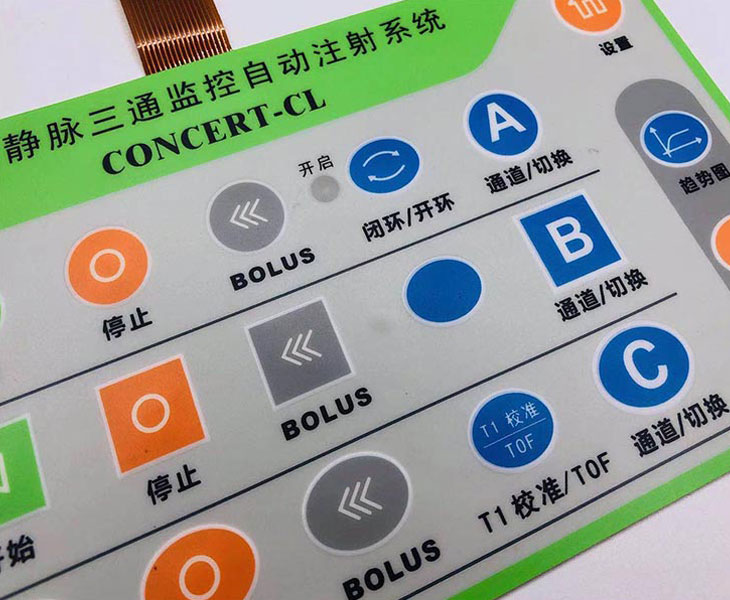

The indicator light (visual) of the membrane switch, the ticking sound of pressing the shrapnel (auditory) or the blind spot (tactile) can be used to reduce operation errors. So Niceone-tech can add LEDs to the membrane switch, button bumping and increase of blind spots to make the product more friendly so that the product is more in line with the human design. Even sometimes the membrane switch is combined with the touch screen, and the instructions of the display are watched to quickly know that the user's request is satisfied.

2. Product tightness

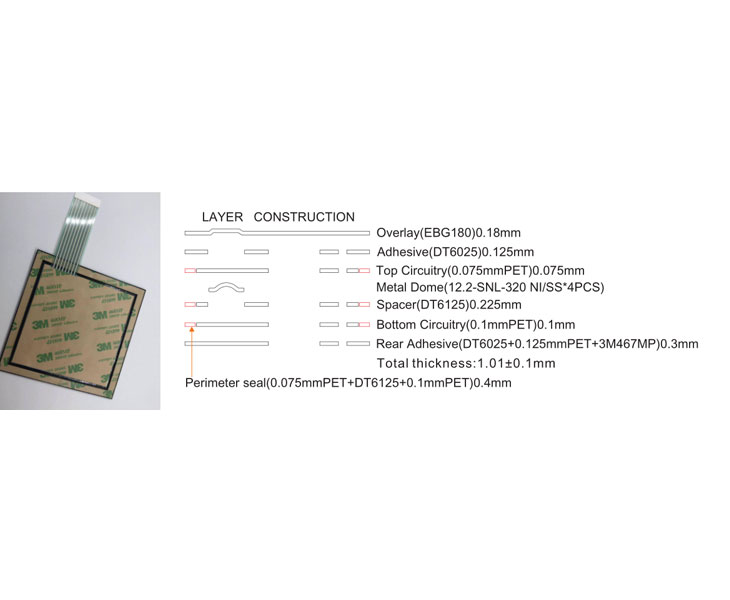

Wiping with chemicals and cleaning materials for a long time, the membrane switch is prone to water ingress and electrical performance is damaged. Although most membrane switches can reach IP65 and can meet most medical environments, when users need to reach IP67 or higher, we would highly recommend customers to use waterproof frame membrane switches. In this way, even if exposed to chemical substances or cleaning substances for a long time, the medical membrane switch can be cleaned for a long time without causing electrical performance failure due to liquid damage. The structure is shown below.

1. Use medical equipment in low-light environments.

In fact, the answer lies in how to make the membrane switch have a backlight effect. Simply put, choosing a led membrane switch can meet these requirements and complete the customer's challenge. Backlight membrane switch is mainly the collective name of EL membrane switch, optical fiber membrane switch and LGF membrane switch. There is also a membrane switch of the phosphor series. But the effect is not as good as these three types of effects, but it is very cost-effective.

A. EL membrane switch - uses phosphor to convert electrical energy into light energy.

Advantages: The brightness of the product is very uniform, and the EL sheet generally serves as the fixed layer of the metal dome, so the Tactile feedback is better. There are more choices for luminous colors.

Disadvantages of EL film: the brightness of the product will gradually decrease with the use of time, and the general life span is only 2-3000h. At the same time, a higher voltage is required to light the product.

B. Optical fiber membrane switch, which uses fiber as a conduit material, and at the same time uses a plastic shell at the end to bind it together and use LEDs to pair with it.

Advantages: The thickness of the product is generally about 0.2mm, and the material can be used in extreme environments without any influence. The life span is more than 10,000h. The entire product has very uniform luminosity and low power consumption

Disadvantages: The materials are very expensive.

C. The LGF membrane switch-material is a light guide plate made of PET or PC, and a reflective film independently developed by Niceone-tech is added. The light guide plate uses the light source of LEDs to refract into the entire button.

Advantages: moderate price, lifespan up to 10,000h, uniform light, thin product thickness. There are many light colors to choose from.

Disadvantages: The membrane switch whose buttons are too close to the edge cannot use the LGF structure.

D. Fluorescent Membrane switch- After using fluorescent ink to add to the printing ink, the ink can continue to glow in the dark for a period of time after absorbing light.

Advantages: The price is very economical.

Disadvantages: Can not emit light for a long time, and the optional color of the luminous ink is relatively single, and the fluorescent ink cannot be convex.

Although the membrane switch looks very simple, how to meet the needs of medical equipment factories is not a simple science. We believe that after overcoming the challenges of these products, your medical equipment will be more competitive in the medical industry. It is the reliability, ease of cleaning and cost-effectiveness of membrane switches that make them shine in medical equipment.