In the fast-paced world of technology, where every second counts and precision is paramount, electrical switches play a vital role in ensuring seamless functionality. One innovative solution that has gained increasing prominence is the electrical switch sealed membrane. In this article, we will delve into the intricacies of this cutting-edge technology, understanding its construction, applications, advantages, and how it is shaping the future of various industries.

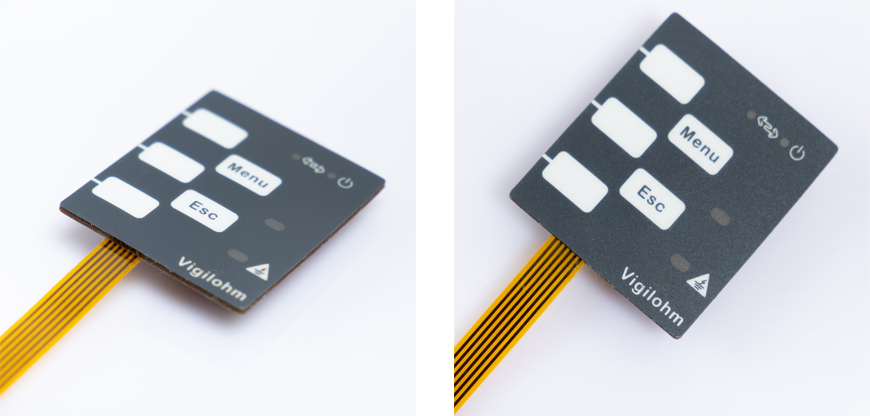

Electrical switch sealed membranes are integral components in a wide range of modern electronic devices. These switches provide an intuitive, durable, and waterproof solution for controlling electronic functions in industries ranging from consumer electronics to industrial machinery. Unlike traditional mechanical switches, sealed membrane switches use a flexible, multi-layer design that offers enhanced resistance to harsh environments while remaining cost-effective and reliable.

Sealed membrane switches are known for their ability to protect sensitive circuits from moisture, dust, and chemicals, making them ideal for applications where durability is essential. As industries demand more compact, versatile, and robust solutions, the role of sealed membrane switch has expanded significantly.

The construction of an electrical switch sealed membrane involves several key components.

The graphic overlay is the outermost layer of the membrane switch. It acts as the first line of defense against the environment and serves as the user interface. This layer is typically made of a durable, flexible material like polyester or polycarbonate, printed with graphics, symbols, icons, or labels to indicate the various functions of the device. These visuals help users identify button locations, and some overlays also include backlighting or LED indicators to improve visibility in low-light conditions.

In addition to providing a user interface, the graphic overlay also provides protection to the underlying components, shielding them from moisture, dirt, and other external factors that could compromise performance.

The spacer layer is a critical component placed directly beneath the graphic overlay. It is typically made of an insulating material that provides physical separation between the upper and lower circuit layers. The spacer layer contains precisely placed holes or domes that align with the locations of the switch points. These domes create the necessary gap between the conductive layers, allowing for the switching mechanism to function effectively. When pressure is applied to the overlay, the spacer layer compresses, causing the top and bottom circuit layers to connect and complete the circuit.

The circuit layer is where the magic happens. It contains conductive traces or printed circuits that are designed to carry the electrical current. When a user presses a specific area of the graphic overlay, the spacer layer compresses, allowing the conductive traces on the circuit layer to come into contact with a corresponding trace on the lower circuit layer. This contact closes the electrical circuit, triggering the function associated with the switch. The circuit layer is typically made from copper or other conductive materials that are printed onto a flexible substrate, allowing the switch to maintain its compact and lightweight design.

The adhesive layer holds the entire membrane switch assembly in place, securing it to the surface of the device or control panel. The adhesive used is typically pressure-sensitive, allowing for easy application during manufacturing, while providing a strong, durable bond once in place. The adhesive layer ensures that the membrane switch remains intact over time, even in environments subject to vibration, moisture, or temperature changes.

The working mechanism of a sealed membrane switch is simple yet effective. When pressure is applied to a specific area of the graphic overlay, the following process occurs:

Pressure Activation: Pressing a button or area on the graphic overlay causes the overlay to compress and push against the spacer layer.

Contact: The spacer layer has holes or domes that align with the switch locations. As pressure is applied, the upper and lower circuit layers come into direct contact at the switch point.

Circuit Completion: Once the circuit layers make contact, the electrical circuit is closed, allowing current to flow and activating the associated function or device.

Return to Resting Position: When the pressure is released, the spacer layer returns to its original position, separating the circuit layers again and opening the circuit, which deactivates the switch.

This mechanism enables users to control devices with a simple touch, offering a highly responsive, user-friendly experience.

Electrical switch sealed membranes find applications in a wide range of industries, including:

Medical Devices: Used in equipment with stringent cleanliness requirements.

Industrial Control Panels: Ideal for rugged and harsh environments.

Consumer Electronics: Present in appliances, remote controls, and more.

Aerospace: Ensuring reliability in critical systems.

Automotive: Enhancing user interface in vehicles.

Military and Defense: Meeting durability and reliability standards.

Durability: Resistant to moisture, dust, and chemicals.

Customization: Easily tailored to specific design and branding requirements.

Sensitivity: Responsive to light touch, reducing user fatigue.

Cost-Effective: Efficient production processes make them affordable.

Space-Efficient: Thin and compact design saves valuable space.

Q: Are sealed membrane switches waterproof?

A: Yes, sealed membrane switches are typically waterproof and resistant to moisture and dust.

Q: Can membrane switches be used in extreme temperatures?

A: Membrane switches may not perform well in extreme temperatures, so it's essential to consider the operating environment.

Q: How long do sealed membrane switches typically last?

A: With proper care and maintenance, sealed membrane switches can last for many years.

Q: Are membrane switches easy to clean?

A: Yes, their sealed design makes them easy to clean and maintain.

Q: Can membrane switches be customized for specific functions?

A: Absolutely, membrane switches offer a high degree of customization to meet specific design and functionality requirements.